By Li Xinyi, Li Yan, Wang Hailin, People's Daily

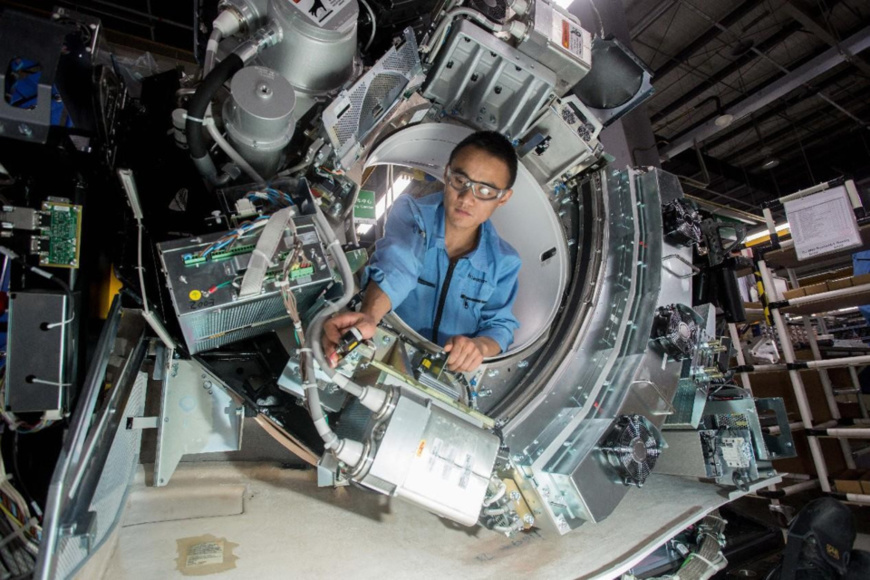

At the GE HealthCare Beijing Imaging Equipment Manufacturing Base, located at No. 1 Yongchang North Road in Beijing Economic and Technological Development Area, production lines were humming as medical devices were assembled one after another.

Two out of every three CT scanners sold globally by GE HealthCare are produced here, and products manufactured at the base are sold to over 100 countries and regions worldwide.

"When we entered Beijing Economic and Technological Development Area 33 years ago, this place was mostly farmland and livestock farms. From the beginning, we firmly believed that we could achieve long-term growth in the Chinese market. Today, this has become GE HealthCare's largest imaging equipment production base globally. This success came from China's continuously improving business environment, stable and smooth industrial and supply chains, and steadily increasing innovation capabilities," said Zhang Yihao, vice president of GE Healthcare and president and CEO of GE Healthcare China, during an interview with People's Daily.

In 1991, GE HealthCare established GE Hangwei Medical Systems, Co., Ltd. in China. It was GE HealthCare's first joint venture in China and one of the earliest companies to settle in the Beijing Economic and Technological Development Area.

Over the past 30-plus years, the company has achieved rapid development there. Currently, the GE HealthCare Beijing Imaging Equipment Manufacturing Base is able to produce CT scanners ranging from 16-slice to 256-slice, molecular imaging equipment, surgical systems, angiography systems, bone densitometers, nuclear medicine PET/CT equipment, as well as components such as detectors and X-ray tubes. Its product design and manufacturing processes for CT equipment components are leading globally.

Now, GE HealthCare has six major production bases and seven factories located in Beijing, Shanghai, Wuxi, Tianjin, Chengdu, and Shenzhen. The continuous improvement in GE HealthCare's localized production in the Chinese market is inseparable from China's stable and smooth industrial and supply chains.

It is learned that GE HealthCare has over 1,000 suppliers in China, including more than 160 core suppliers. Zhang said that China is working to optimize its economic structure, supporting cooperation between Chinese and foreign enterprises, accelerating the implementation of advanced digital technologies, products, and solutions. This contributes to building a global industrial and supply chain system that is secure, stable, smooth, efficient, open, inclusive and mutually beneficial.

In recent years, Beijing Economic and Technological Development Area has built a 100-billion-yuan ($13.8 billion)-scale biological technology and health industry cluster, attracting over 4,200 biotech and health companies. Cooperation between upstream and downstream sectors of the industrial and supply chains has been further strengthened.

On a orthopedic surgical equipment production line at the GE HealthCare Beijing Imaging Equipment Manufacturing Base, automated testing robots responsible for equipment final testing were simultaneously calibrating and testing six CT devices. Human-machine collaborative testing robots and AI-based automatic testing systems for surgical equipment worked closely together to complete position corrections and radiation dose measurements at nine test points.

This is the world's first fully automated "testing tunnel," developed by GE HealthCare's Chinese team. It requires only 15 workers to produce over 2,000 sets of products annually, with one surgical system rolling off the line every 50 minutes on average. Both product quality and work efficiency have been greatly improved.

Currently, GE HealthCare has about 1,800 R&D personnel in China, with over 1,000 R&D staff and more than 160 R&D laboratories in Beijing alone. Over the past decade, the company's Chinese team has developed and launched over 120 products. Among these, the CT scanner equipped with the "Skeye" digital solution based on deep learning and AI technologies has become the "star product" of GE HealthCare. Of the Class III medical device licenses approved for the company in China, 77 percent of the product technologies were developed by the Chinese team and registered in China.

"In recent years, China has implemented an innovation-driven development strategy, rapidly advancing its technological capabilities. The abundant innovative elements have helped us gain a competitive edge in the global market," Zhang stated.

He added that China is accelerating the development of new quality productive forces and actively fostering emerging and future industries. "We look forward to deepening cooperation with our Chinese partners to further promote development in relevant fields."

Zhang emphasized that GE HealthCare has been both a witness to and beneficiary of China's continuous expansion of opening up. "As China's door opens wider, and the level of openness continues to rise, it will undoubtedly bring broader development opportunities for multinational companies and provide stronger momentum for global economic recovery and growth."

Two out of every three CT scanners sold globally by GE HealthCare are produced here, and products manufactured at the base are sold to over 100 countries and regions worldwide.

"When we entered Beijing Economic and Technological Development Area 33 years ago, this place was mostly farmland and livestock farms. From the beginning, we firmly believed that we could achieve long-term growth in the Chinese market. Today, this has become GE HealthCare's largest imaging equipment production base globally. This success came from China's continuously improving business environment, stable and smooth industrial and supply chains, and steadily increasing innovation capabilities," said Zhang Yihao, vice president of GE Healthcare and president and CEO of GE Healthcare China, during an interview with People's Daily.

In 1991, GE HealthCare established GE Hangwei Medical Systems, Co., Ltd. in China. It was GE HealthCare's first joint venture in China and one of the earliest companies to settle in the Beijing Economic and Technological Development Area.

Over the past 30-plus years, the company has achieved rapid development there. Currently, the GE HealthCare Beijing Imaging Equipment Manufacturing Base is able to produce CT scanners ranging from 16-slice to 256-slice, molecular imaging equipment, surgical systems, angiography systems, bone densitometers, nuclear medicine PET/CT equipment, as well as components such as detectors and X-ray tubes. Its product design and manufacturing processes for CT equipment components are leading globally.

Now, GE HealthCare has six major production bases and seven factories located in Beijing, Shanghai, Wuxi, Tianjin, Chengdu, and Shenzhen. The continuous improvement in GE HealthCare's localized production in the Chinese market is inseparable from China's stable and smooth industrial and supply chains.

It is learned that GE HealthCare has over 1,000 suppliers in China, including more than 160 core suppliers. Zhang said that China is working to optimize its economic structure, supporting cooperation between Chinese and foreign enterprises, accelerating the implementation of advanced digital technologies, products, and solutions. This contributes to building a global industrial and supply chain system that is secure, stable, smooth, efficient, open, inclusive and mutually beneficial.

In recent years, Beijing Economic and Technological Development Area has built a 100-billion-yuan ($13.8 billion)-scale biological technology and health industry cluster, attracting over 4,200 biotech and health companies. Cooperation between upstream and downstream sectors of the industrial and supply chains has been further strengthened.

On a orthopedic surgical equipment production line at the GE HealthCare Beijing Imaging Equipment Manufacturing Base, automated testing robots responsible for equipment final testing were simultaneously calibrating and testing six CT devices. Human-machine collaborative testing robots and AI-based automatic testing systems for surgical equipment worked closely together to complete position corrections and radiation dose measurements at nine test points.

This is the world's first fully automated "testing tunnel," developed by GE HealthCare's Chinese team. It requires only 15 workers to produce over 2,000 sets of products annually, with one surgical system rolling off the line every 50 minutes on average. Both product quality and work efficiency have been greatly improved.

Currently, GE HealthCare has about 1,800 R&D personnel in China, with over 1,000 R&D staff and more than 160 R&D laboratories in Beijing alone. Over the past decade, the company's Chinese team has developed and launched over 120 products. Among these, the CT scanner equipped with the "Skeye" digital solution based on deep learning and AI technologies has become the "star product" of GE HealthCare. Of the Class III medical device licenses approved for the company in China, 77 percent of the product technologies were developed by the Chinese team and registered in China.

"In recent years, China has implemented an innovation-driven development strategy, rapidly advancing its technological capabilities. The abundant innovative elements have helped us gain a competitive edge in the global market," Zhang stated.

He added that China is accelerating the development of new quality productive forces and actively fostering emerging and future industries. "We look forward to deepening cooperation with our Chinese partners to further promote development in relevant fields."

Zhang emphasized that GE HealthCare has been both a witness to and beneficiary of China's continuous expansion of opening up. "As China's door opens wider, and the level of openness continues to rise, it will undoubtedly bring broader development opportunities for multinational companies and provide stronger momentum for global economic recovery and growth."

Menu

Menu

China's opening up brings broad opportunities for multinational corporations

China's opening up brings broad opportunities for multinational corporations