By Zhu Lei, People's Daily

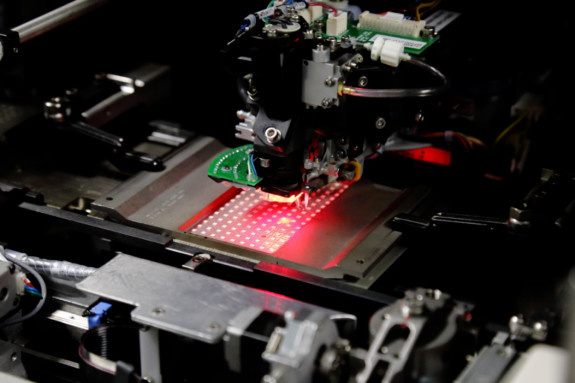

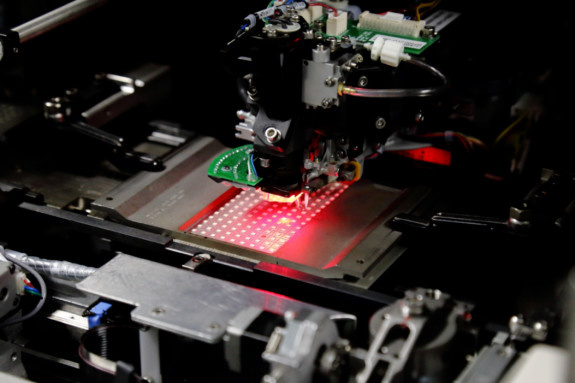

Photo shows a wire bonder of the packaging line of LatticePower in east China's Jiangxi province. (File photo)

About one out of every three smartphones worldwide utilizes silicon substrate-based LED for its phone flash. Similarly, for every three flashlights in the world, there is one with such technology.

In fact, many cities in China have extensively adopted silicon substrate-based LED chips for road and tunnel lighting.

Silicon substrate-based LED has become one of the three major technology pathways in the global LED industry. Nanchang, capital of east China's Jiangxi province, is exactly where this technology started.

LED stands for light-emitting diode, which is a third-generation semiconductor light source. As an energy-saving and environmentally friendly cold light source, it is a fundamental component of the electronic information industry and has a wide range of applications.

At the beginning of this century, the common substrates for blue LED chips were sapphire or silicon carbide, and the two technical routes have been industrialized. However, the dominance of these technologies was largely held by developers outside China.

"At that time, we aimed at the unpopular technology direction of growing gallium nitride-based materials on silicon substrates," said Jiang Fengyi, a professor from Nanchang University. According to him, this was a path that had been almost abandoned by foreign developers.

In the production of LEDs, the growth of upstream materials to a large extent decides the LED color, brightness, lifespan, and other indicators. To produce LED chips, it is necessary to grow a gallium nitride light-emitting film on a substrate.

However, there are serious thermal and lattice mismatches between silicon and gallium nitride materials. Researchers around the world had not yet found an ideal solution despite years of efforts.

On Nov. 27, 2003, Jiang and his team embarked on a challenging exploration. In 2004, After more than 4,000 trial and error attempts, Jiang's team became the first in the world to overcome this key technical difficulty.

"This will be a brand new arena," said Wang Min, who worked together with Jiang. Wang keenly sensed the potential transformative impact this technology could bring to the industry.

Since then, Wang and Jiang co-founded tech firm LatticePower to promote the industrialization of silicon substrate-based blue LEDs. In October 2007, LatticePower officially settled in the Nanchang National High-tech Industrial Development Zone.

After years of development, in 2012, the company successfully achieved mass production of high-power LED chips on silicon substrates, which was praised as an annual new event by the International SSL Alliance.

In order to better open up the market, Wang decided to go for vertical integration - packaging LatticePower's own LEDs. In 2014, a ceramic packaging line was officially launched, enabling the mass production of its own "light bulbs.

Since then, LatticePower's LED products have made great strides with higher cost-effectiveness, eventually capturing around 30 percent of the global mobile lighting market. LatticePower Semiconductor Corporation, a subsidiary of LatticePower, boasts a monthly production capacity of up to 100 million units.

In the product showcase area of LatticePower, there are nearly 100 types of products on display, including large LED high-definition screens, streetlights, and smartphone flashlights. Today, LatticePower has grown into a leading semiconductor optoelectronic device manufacturer, offering products that span the entire industrial chain to customers worldwide.

In addition to the packaging line, LatticePower is continuously expanding its industrial ecosystem. With strong government support, it has attracted well-known venture capital funds such as GSR United Capital to establish sub-funds in Nanchang, successively incubated Lattice Lighting and Lattice Grand Technology, and introduced companies such as ShineOn and Kingsoon to promote the ecosystem of the silicon substrate-based LED industry.

Relying on silicon substrate-based LED technology, Nanchang has carved out a path of independent innovation in the global LED industry. Today, the technology continues to produce world-class innovative achievements such as yellow and red LEDs.

Driven by such innovation and the support of relevant government policies, Nanchang has established a complete LED industry chain, becoming the largest production base for high-power LED light sources in China.

In 2019, a 1-billion-yuan ($140.58 million) fund was established to amplify the application advantages of silicon substrate-based LED technology, which attracted a number of leading domestic LED companies such as Shenzhen MTC, Xiamen Changelight, and Hongli Zhihui Group. In 2022, the LED industry in Nanchang achieved a revenue of 21.2 billion yuan.

According to the plan, the city will focus on the manufacturing and packaging of LED chips to build itself into a "light valley." In particular, the Nanchang National High-tech Industrial Development Zone will concentrate on building a complete LED industry chain cluster with a focus on silicon substrate-based LEDs, and the Nanchang Economic and Technological Development Zone will prioritize the development of basic materials, chip packaging, and terminal applications. Besides, other districts and counties will focus on developing supporting links in the industrial chain. The goal is to expand Nanchang's LED industry scale to 50 billion yuan by 2026.

In fact, many cities in China have extensively adopted silicon substrate-based LED chips for road and tunnel lighting.

Silicon substrate-based LED has become one of the three major technology pathways in the global LED industry. Nanchang, capital of east China's Jiangxi province, is exactly where this technology started.

LED stands for light-emitting diode, which is a third-generation semiconductor light source. As an energy-saving and environmentally friendly cold light source, it is a fundamental component of the electronic information industry and has a wide range of applications.

At the beginning of this century, the common substrates for blue LED chips were sapphire or silicon carbide, and the two technical routes have been industrialized. However, the dominance of these technologies was largely held by developers outside China.

"At that time, we aimed at the unpopular technology direction of growing gallium nitride-based materials on silicon substrates," said Jiang Fengyi, a professor from Nanchang University. According to him, this was a path that had been almost abandoned by foreign developers.

In the production of LEDs, the growth of upstream materials to a large extent decides the LED color, brightness, lifespan, and other indicators. To produce LED chips, it is necessary to grow a gallium nitride light-emitting film on a substrate.

However, there are serious thermal and lattice mismatches between silicon and gallium nitride materials. Researchers around the world had not yet found an ideal solution despite years of efforts.

On Nov. 27, 2003, Jiang and his team embarked on a challenging exploration. In 2004, After more than 4,000 trial and error attempts, Jiang's team became the first in the world to overcome this key technical difficulty.

"This will be a brand new arena," said Wang Min, who worked together with Jiang. Wang keenly sensed the potential transformative impact this technology could bring to the industry.

Since then, Wang and Jiang co-founded tech firm LatticePower to promote the industrialization of silicon substrate-based blue LEDs. In October 2007, LatticePower officially settled in the Nanchang National High-tech Industrial Development Zone.

After years of development, in 2012, the company successfully achieved mass production of high-power LED chips on silicon substrates, which was praised as an annual new event by the International SSL Alliance.

In order to better open up the market, Wang decided to go for vertical integration - packaging LatticePower's own LEDs. In 2014, a ceramic packaging line was officially launched, enabling the mass production of its own "light bulbs.

Since then, LatticePower's LED products have made great strides with higher cost-effectiveness, eventually capturing around 30 percent of the global mobile lighting market. LatticePower Semiconductor Corporation, a subsidiary of LatticePower, boasts a monthly production capacity of up to 100 million units.

In the product showcase area of LatticePower, there are nearly 100 types of products on display, including large LED high-definition screens, streetlights, and smartphone flashlights. Today, LatticePower has grown into a leading semiconductor optoelectronic device manufacturer, offering products that span the entire industrial chain to customers worldwide.

In addition to the packaging line, LatticePower is continuously expanding its industrial ecosystem. With strong government support, it has attracted well-known venture capital funds such as GSR United Capital to establish sub-funds in Nanchang, successively incubated Lattice Lighting and Lattice Grand Technology, and introduced companies such as ShineOn and Kingsoon to promote the ecosystem of the silicon substrate-based LED industry.

Relying on silicon substrate-based LED technology, Nanchang has carved out a path of independent innovation in the global LED industry. Today, the technology continues to produce world-class innovative achievements such as yellow and red LEDs.

Driven by such innovation and the support of relevant government policies, Nanchang has established a complete LED industry chain, becoming the largest production base for high-power LED light sources in China.

In 2019, a 1-billion-yuan ($140.58 million) fund was established to amplify the application advantages of silicon substrate-based LED technology, which attracted a number of leading domestic LED companies such as Shenzhen MTC, Xiamen Changelight, and Hongli Zhihui Group. In 2022, the LED industry in Nanchang achieved a revenue of 21.2 billion yuan.

According to the plan, the city will focus on the manufacturing and packaging of LED chips to build itself into a "light valley." In particular, the Nanchang National High-tech Industrial Development Zone will concentrate on building a complete LED industry chain cluster with a focus on silicon substrate-based LEDs, and the Nanchang Economic and Technological Development Zone will prioritize the development of basic materials, chip packaging, and terminal applications. Besides, other districts and counties will focus on developing supporting links in the industrial chain. The goal is to expand Nanchang's LED industry scale to 50 billion yuan by 2026.

Menu

Menu

China's Nanchang carves out remarkable development path with LED technology

China's Nanchang carves out remarkable development path with LED technology